Pumps

A water cooling system consists of a large number of components to ensure the best possible cooling. However, this cooling can only function if the cooling liquid is conveyed within the cooling system - in other words, if it is in a constant flow.

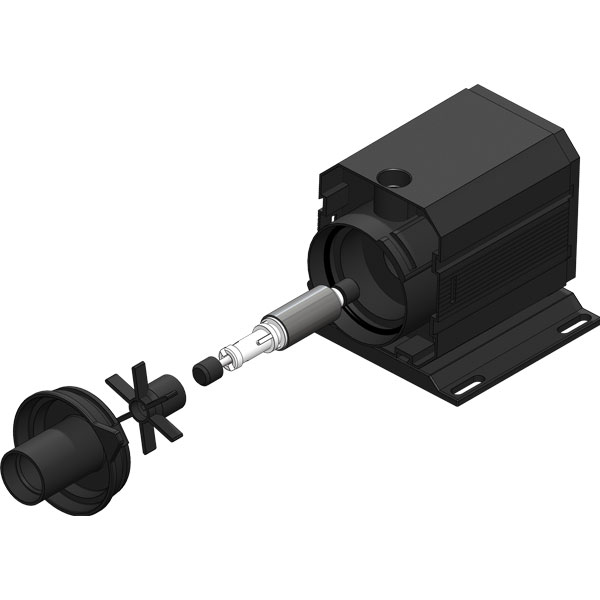

To achieve this, we usually use pumps without moving seals (mainly centrifugal pumps) in a water cooling system - usually in the form of a 12V or also 24V pump with high-quality bearings in the case of smaller systems. These wet-running pumps have static, i.e. non-moving seals. For larger installations we use multistage pumps with 230V or also 400V. For dry pumps we use magnetically coupled versions.

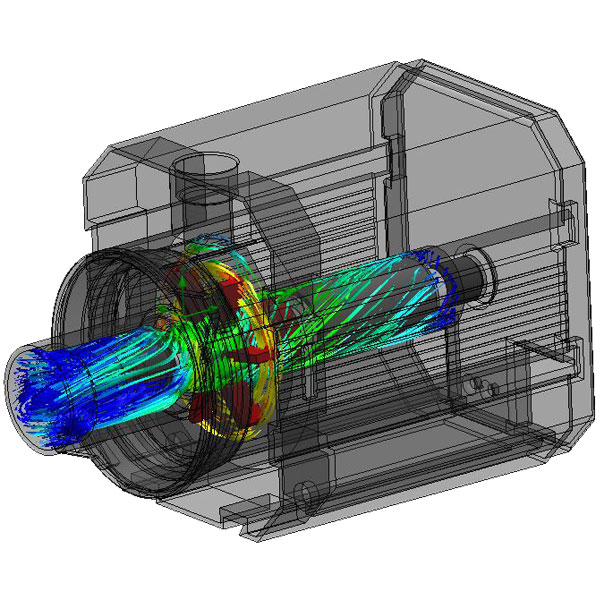

With the help of a rotating shaft inside the pump, the dynamic forces are used to pump the coolant in order to ensure a uniform flow of the coolant and thus to transport the power loss transferred from the heat sinks to the coolant to the heat exchangers (radiators).

The flow of a pump

The movement of the cooling liquid is also commonly referred to as flow rate (volume flow) and should always reach a speed oriented to the demand of the system (power conversion).

If the flow rate is too slow (low), the coolant heated by the radiators can no longer be discharged quickly enough with sufficient temperature difference, which has a negative effect on cooling performance.

A flow rate that is too fast (high) brings only marginal to partially no longer measurable improvements and is rather counterproductive in terms of the economic efficiency of the system. Therefore, it is enormously important that the pump used achieves a flow rate optimized for the system's needs.

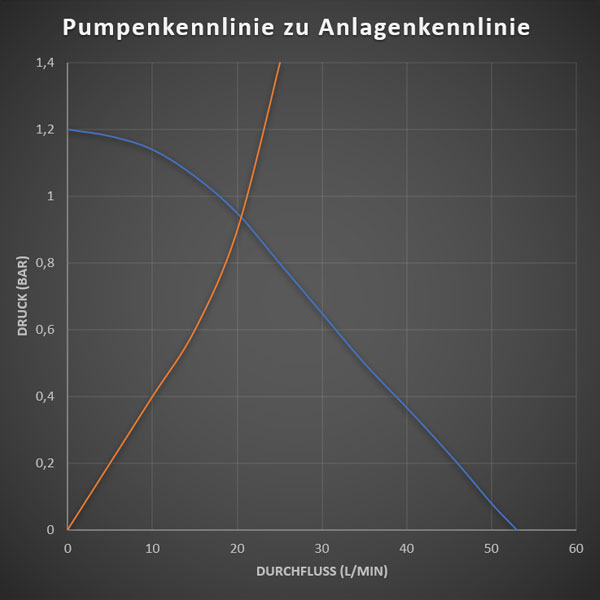

The head of a pump

In addition to the volume flow, the so-called delivery head is also a decisive factor in the selection of the appropriate pump to ensure the delivery of the coolant against the hydraulic consumption of the system. The delivery head corresponds to the pressure that the pump itself can reach.

For the initial filling and venting of the cooling system, overcoming the height differences is important. Once a cooling system is filled, the difference in height of the components contained in the circuit is no longer relevant.

Depending on the performance, our high-quality pumps can also easily manage several meters of height difference.

Examples of units and dependencies at a glance:

| bar (Pressure) | mWs (Meters water column) | pa (Pascal) | psi (Pounds per square inch) |

| 0,25 | 2,54 | 25.000 | 3,62 |

| 0,50 | 5,08 | 50.000 | 7,25 |

| 1,00 | 10,19 | 100.000 | 14,50 |

| 1,50 | 15,28 | 150.000 | 21,75 |

With the help of the pumps we offer, any water cooling system can be operated optimally. Our pumps differ not only in their dimensions, but also in terms of flow rate, head and volume. What they all have in common is an extremely high durability, outstanding quality and easy integration into existing as well as planned cooling systems.

Do you still have questions about our pumps? We would be happy to discuss your customer-specific wishes and requirements with you. Please contact our sales department directly at +49 (0) 8405 / 9259-0 or send us an email with your requirements.