Peltier cooling

Modern power electronics are not only very powerful, they also generate immensely high levels of waste heat - which, if not cooled sufficiently, can lead to instability, failure or even destruction of the component being cooled.

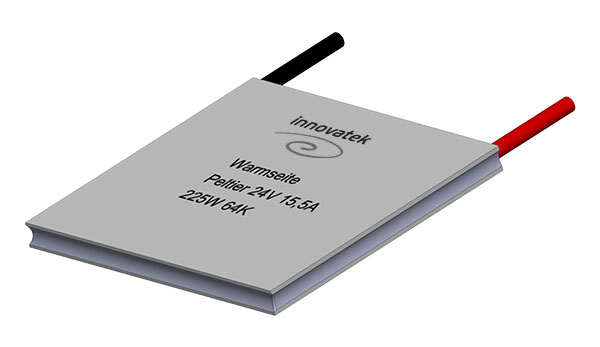

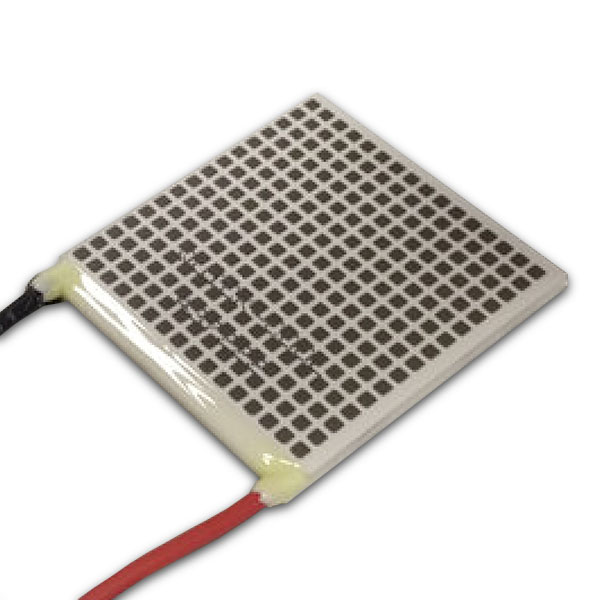

A Peltier element for cooling heat sources

A Peltier element for cooling heat sources

For the dissipation of high waste heat (power loss), the use of a high-performance Peltier cooling system (thermoelectric cooling) is therefore recommended, which, in addition to compact dimensions, can also convince with a precise and extremely effective heat transfer.

But how does such Peltier cooling work?

Peltier cooling is also commonly referred to as a Peltier element. It is constructed in a sandwich process and usually contains the following components:

- two plates made of ceramic substrate (e.g. alumina ceramic)

- mostly square conductors made of semiconductor material (n- and p-doped, always in pairs)

- Metal bridges for alternating contacting

In the classic Peltier element, a large number of the square conductors are placed between the two insulating ceramic plates, with the metal bridges connecting the conductors in the form of a series connection.

During operation, the electric current flows successively through the conductors inside the Peltier cooler, with the metal bridges acting as thermal contact surfaces. In the course of this, a very high temperature difference is generated between the conductors, whereby the heat is virtually "pumped" through the Peltier element.

The cooling system absorbs the waste heat from the Peltier element and then transports it further. In the case of a high-quality water cooling system, a very high power loss can thus be quickly dissipated to the ambient air through the use of powerful heat exchangers.

How is a Peltier element optimally embedded?

A particularly important point in Peltier cooling is the contact between the Peltier element and the component to be cooled as well as the heat exchanger (cooler). Often, a lot of cooling capacity is wasted here, insofar as an insufficient heat conducting medium is used. For example, when a classic thermal paste is used, the carrier substance migrates out of the contact zone via capillary effects and cooling and heating cycles, and only the dry filler remains between the Peltier element and the heat exchanger. As a result, the waste heat can no longer be optimally dissipated and the Peltier element and the component to be cooled can be damaged!

Also, when used within Peltier cooling, conventional thermal conductors cannot compensate for the "bimetallic effect" created by the different temperature ranges in a Peltier element.

Therefore, it is extremely important that the Peltier element is only used with a thermal conductive agent suitable for this purpose. Especially for Peltier cooling we have developed our innovatek Peltier contact gel, which is available with and without silver filling. The Peltier contact gel offers a very high thermal conductivity and also a re-releasable connection.

Another advantage is its excellent consistency, which enables the contact gel to be applied by screen printing - ideal for series production.

The innovatek Peltier contact gel applied by screen printing